One of the primary concerns regarding fossil fuels today is not only their massive environmental impact but their persistent dominance in the energy field. Growing waste, pollution and energy consumption and demand all prompt the search for alternative, renewable energy sources, for example, biomass. Biomass waste includes agricultural residues, such as crops, crop residues, animal waste, and food scraps. All of these can be thermochemically converted into fuel, chemicals, and other biobased materials for various applications, simultaneously reducing the amount of waste going into landfills. Biomasses are also widely available, have high moisture and volatile matter content, presence of alkali metals in ash, and display a wide range of different physical and chemical properties.

Refuse Derived Fuel (RDF) is another example of waste with high energy potential. RDF is mainly composed of plastic waste, paper, textiles, and wood, containing high organic matter content, giving ita high calorific value. RDF is a fuel produced from municipal solid waste that has been processed to remove non-combustible materials, like metals, glass, and other inorganic materials, leading to relativelystable chemical properties and low moisture content. In return, this gives it a high energy potential. RDF also has a higher energy content than raw municipal solid waste, making it a more efficient fuel source. Itcan be easily transported and stored, making it a convenient fuel source for energy generation in the cement industry or in energy plants. However, the direct combustion of RDF can be potentially unsafe, causing the emission of hazardous substances.

Magdziarz et al., 2024 examines the co-conversion of biomass and RDF, specifically through a process called pyrolysis. Pyrolysis is a thermochemical conversion process carried out in an oxygen-free atmosphere (typically in nitrogen or argon) at a temperature above 300–400 ◦C. This leads to the production of three main products: syngas, pyro-oil (liquid or “bio-oil”), and pyro-char (solid or “bio-char”). Thedistribution of product yields depends directly on the conditions of the process (operational parameters) including the temperature, heating rate, residence time of the volatiles, the particle size of the feedstock, type of feedstock or biomass, etc. The syngas may be useful in generating heat and electricity, while the solid bio-char may be useful as a soil applicant, aiding in carbon sequestration, water retention, and nutrient availability. However, the main focus of this study was to improve the quality and quantity of produced bio-oil, which can be used as a renewable alternative to fossil fuels.

Co-pyrolysis of biomass and RDF was considered a “good solution”, as it helps reduce deposited waste and improves the quality of bio-oil produced by overcoming some of the challenges associated with the pyrolysis of biomass alone, such as poor bio-oil quality due to the presence of impurities. Additionally, the process supports the development of circular economy principles by reducing the dependenceof fossil fuel resources. Previous studies focused on co-pyrolysis of biomass and plastics as opposed to RDF and found that minimizing the concentration of complex liquid compounds and heavy hydrocarbons improved the quality of syngas and liquid products. The addition of catalysts further improved bio-oil quality by increasing the content of hydrocarbons and reducing the content of oxygenated compounds in bio-oil. Pyrolysis of pure RDF can be problematic due to the formation of tar, wax, and other volatile organic compounds, causing equipment damage, reducing product quality, and increasing emissions.

Additionally, Magdziarz et al., 2024 investigated two agricultural biomass feedstocks, rye straw (RS) and agriculture grass (AG), along with RDF, mainly composed of plastics. The pyrolysis process was conducted at 600 ◦C under a nitrogen atmosphere with a mass sample of 1 gram and residence time of 3 minutes. First, the pyrolysis of raw feedstocks was conducted to collect and analyze the properties of solid, liquid, and gas products. Then, co-pyrolysis experiments were conducted to investigate the impact of RDF addition on the properties of products with mixtures of 75:25 and 50:50 weight-percentage ratios (biomass to RDF mass ratio). Respectively, the samples were named: 75RS-25RDF, 75AG-25RDF, 50RS-50RDF, and 50AG-50RDF. RS and AG have similar physical and chemical properties, but AG containsa higher ash content and, consequently, lower volatile matter. Ash content and volatile matter both can influence the yield of products, as ash can catalyze undesirable secondary reactions (char oxidation or tar formation), reducing bio-oil yield, and higher volatile matter content generally correlates with the higher yield of gaseous products. The study analyzed the composition of volatile matter released during the pyrolysis process for both feedstocks and for the mixtures of biomass and RDF.

In the case of the RDF sample, there were over 300 chemical compounds, while the biomass samples released about half as many chemical compounds. Therefore, the released analytes, especially forRDF, may be considered highly complex mixtures composed of compounds with different volatility.

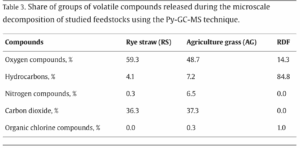

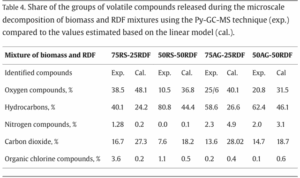

For RS and AG as seen in the table above, the main group of compounds were oxygen compounds. Meanwhile, for RDF, hydrocarbons were the dominant volatile products, and the very low oxygen content for RDF (<2.85 weight%) resulted in a negligible CO2 content, unlike the biomass samples. For the four mixtures of biomass and RDF (75RS-25RDF, 75AG-25RDF, 50RS-50RDF, and 50AG-50RDF), the percentages of the groups of volatile compounds released were compared to the values estimated based on the linear model.

Atomic Share for Varying Mixtures of Biomass Samples by Percentage

In all four samples, the hydrocarbons and their oxygen derivatives were the dominant group of compounds released during co-pyrolysis. The release of hydrocarbons is arguablybeneficial for increasing the application potential of volatile pyrolysis products that can be a type of alternative fuel. Hydrocarbons can enhance the energy value of the fuel and after additional treatment, can be used as by-products to value-added materials. The study also noted that the observed share of hydrocarbons released during pyrolysis was significantly higher than calculated from the linear model, which correlated with the addition of RDF to the biomass samples. The increased percentage of hydrocarbons also correlated with a simultaneous decrease in the relative share of other groups of compounds, especially oxygen compounds, as well as significantly lower CO2 content than expected from the linear model’s calculation.

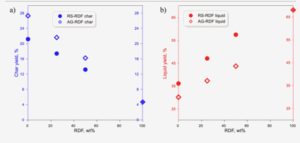

The yields of the bio-char and bio-oil phases are presented in Figure 5 above. The char yield for AG was higher (27.3%) than for RS (21.2%). The addition of 50% RDF to biomass decreased the char yields to 16.2% and 13.2%, respectively. Bio-oil yield was higher for RS (35.9%) than for AG (29.9%). Results from previous studies also show higher bio-oil yields and lower bio-char yieldsas RDF percentage increased. As predicted, co-pyrolysis of RDF with biomass gave a better synergetic effect for RS than for AG with the RS samples producing a higher ratio of bio-oil than the AG samples.The gas yield was calculated by the formula, 100% – char yield – liquid yield, and the pure RS and AG samples had similar gas yields at around 40%. The presence of RDF did not significantly influence gas yield for AG, but for RS (50RS-50RDF) decreased the yield by 13%. Gas yields consisted mainly of CO, CO2, H2, and CH4. The calorific value of gas from RS pyrolysis was higher than for AG. The addition of RDF for both biomasses (50RS-50RDF and 50AG-50RDF) decreased the content of CO and H2 and simultaneously increased the amount of CO2 and CH4 product. However, the study mentions that the gas yields from co-pyrolysis were not a concern, as the main goal was to obtain bio-oil.

The main conclusions for the study were that for mixtures of biomass and RDF the content of oxygen in volatiles was significantly reduced, while the content of hydrocarbons was increased, and co-pyrolysis of biomass and RDF confirmed the benefits of RDF addition, which positively influenced product yields and quality. The co-pyrolysis of the AG and RS (waste materials) with RDF offers another method to contribute to circular economics and sustainable waste management. Co-pyrolysis of biomass and RDF may potentially be effective ways to convert waste into energy and produce useful bio-char, bio-oil, and even various gaseous products. Future studies should focus on the type of feedstock used and various parameters of the pyrolysis process to ensure that the process is as efficient, sustainable, and environmentally friendly as possible.

References

Magdziarz, A., Jerzak, W., Wądrzyk, M., & Sieradzka, M. (2024). Benefits from co-pyrolysis of biomass and refuse derived fuel for biofuels production: Experimental investigations. Renewable Energy, 230, 120808. https://doi.org/10.1016/j.renene.2024.120808